Create Outstanding Client Experiences

Elevate Client Conference

June 11-13, 2024 • Park City, Utah, USA

Simplify the Complex

Trusted by thousands of companies worldwide

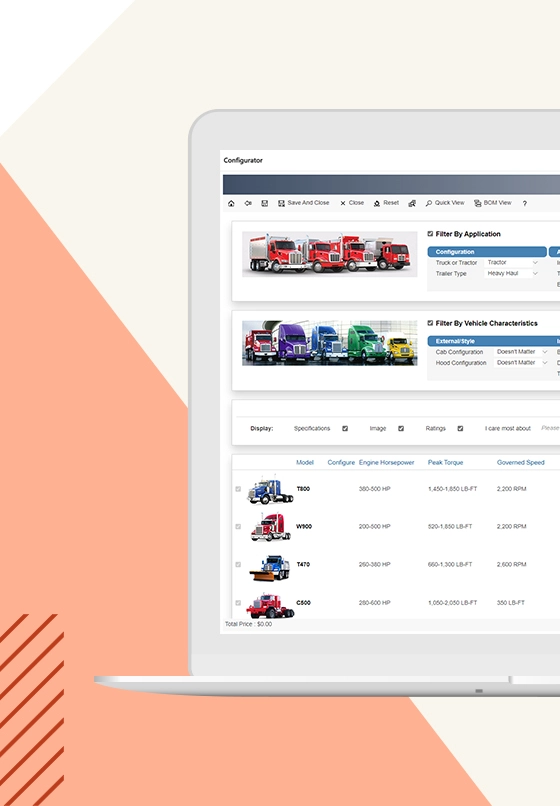

Configure, Price, Quote

Empower Sales Teams

with CPQ

Simplify and accelerate your quote & order processes to help your sales reps sell faster and more accurately.

Low Code/No Code Administration

Our intuitive modeling environment enables business users to deploy and maintain CPQ faster than traditional CPQs.

Seamless integrations

Guided selling

Help sales find more upsell and cross-sell opportunities with personalized messages.

Improved order accuracy

Deliver Engaging, Accurate Files with Document Automation

Precise Data Collection

Intuitive Template Design

Powerful Document Generation

Streamlined Document Flows

Integrate Experlogix

with Your Key Systems

Experlogix’s suite of business applications feature out of the box integrations with leading business systems.

Digital Commerce

Drive Online Growth with Digital Commerce

Make it easier for your customers to buy and self-serve online using fully integrated digital tools designed for B2B, B2C and D2C sales channels.

Seamless ERP Integrations

Highly Configurable

SaaS Product

Our future-proof products enable a fast time to market and can quickly adapt to business changes.

Business Mobility

Take advantage of out-of-the-box mobile apps, now an essential part of digital commerce to increase sales and grow brand loyalty.

Operational Efficiency

Reduce duplication of data and systems to decrease order processing costs and improve customer service.

Client Stories

Client Success Stories

Read the remarkable success stories of companies like yours, who are enjoying the benefits of Experlogix’s suite of business applications.

Bill Champion | Product and Service Development Director

Read More

See Experlogix Software in Action

You don’t just have to take our word for it. Get in touch with our team to see a demo.